WEW-300D Microcomputer screen display hydraulic universal testing machine

DESCRIPTION:

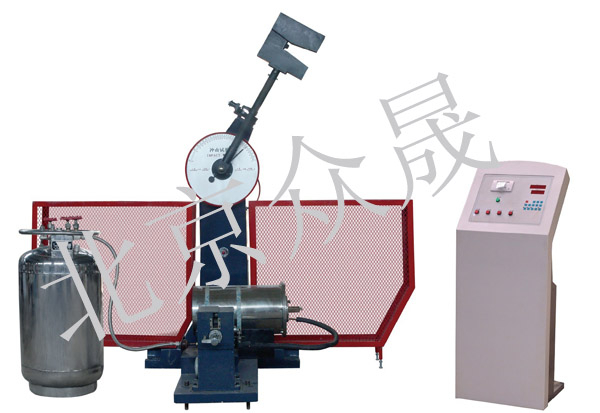

WEW-300D Microcomputer screen display hydraulic universal testing machine

I. Overview

This testing machine is a lower hydraulic universal testing machine, mainly used for metal materials and cement, concrete, plastics and other non-metallic materials such as tensile, compression, bending, shear and other tests. Add accessories, can complete the stranded steel wire, steel wire rope, chain, welding rod, tape and mechanical properties of the component test. Widely used in machinery, metallurgy, transportation, construction, building materials, colleges and universities, quality inspection and other industries and departments. Reliable performance, economical and practical, is the ideal testing machine for material testing in production and engineering.

This testing machine according to the national GB/T3159-2008 "hydraulic universal testing machine" design and manufacture. It adopts hydraulic loading, hydraulic transducer to measure the force, electronic derivation meter to test the tensile deformation, and computer to process the operation data, with the functions of test data screen display and storage, curve drawing and analyzing, printing results, and so on.

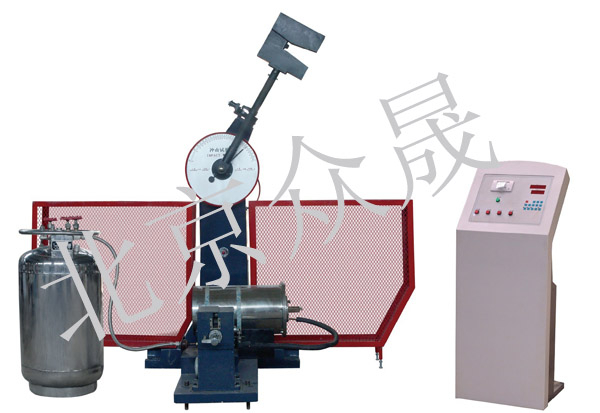

WEW-300D Microcomputer screen display hydraulic universal testing machine

I. Overview

This testing machine is a lower hydraulic universal testing machine, mainly used for metal materials and cement, concrete, plastics and other non-metallic materials such as tensile, compression, bending, shear and other tests. Add accessories, can complete the stranded steel wire, steel wire rope, chain, welding rod, tape and mechanical properties of the component test. Widely used in machinery, metallurgy, transportation, construction, building materials, colleges and universities, quality inspection and other industries and departments. Reliable performance, economical and practical, is the ideal testing machine for material testing in production and engineering.

This testing machine according to the national GB/T3159-2008 "hydraulic universal testing machine" design and manufacture. It adopts hydraulic loading, hydraulic transducer to measure the force, electronic derivation meter to test the tensile deformation, and computer to process the operation data, with the functions of test data screen display and storage, curve drawing and analyzing, printing results, and so on.

Second, the technical parameters and indicators:

1, the maximum test force: 300 kN

2, Accuracy of display value: ± 1%

3, the maximum distance between the tension jaws: 550mm (including cylinder stroke)

4, flat specimen clamping diameter: 0-15mm

5, Round specimen clamping diameter: Φ10-32mm

6, Distance of compression space: 450mm

7, Working piston stroke: 200mm

8, the maximum permissible relative error ±1% of the display value

9, bending test roller spacing: 30-400mm

10, the distance between the two pillars: 460mm

11, the upper and lower pressure plate diameter: 120mm

12, bending pressure roller diameter: Ф30mm

13, clamping: hydraulic clamping

14, oil pump motor power: 2.2KW

15, beam moving motor power: 0.37KW

16, host size: 740 × 580 × 1890mm

17, Size of oil source: 1020×620×810mm

18, Weight: 2200kg

Third, the main accessories configuration

1, round specimen jaws Ф10 ~ Ф20 1 payment

2, round specimen jaws Ф20 ~ Ф32 1 payment

3, flat specimen jaws 0 ~ 15 1 payment

4, pressure attachment upper and lower pressure plate, spherical seat plate 1 set

5, bending test attachment 1 set

6, foot nut screws 4

7, a set of measurement and control system, including (Lenovo computer, HP laser printer, an oil pressure sensor,

An electronic extensometer, a set of special measurement and control software (installed in the microcomputer))